In laboratory workflows, unseen threats like aerosol contamination, residual liquid carryover, and cross-contamination can silently sabotage experimental results. This is where filter pipette tips step in—not just as disposable tools for liquid handling, but as critical safeguards for both sample integrity and instrument longevity.

Filter tips act as the first line of defense by blocking aerosols and liquids from entering the pipette barrel, preventing cross-contamination between samples and protecting sensitive experiments (e.g., PCR, RNA/DNA work) from enzymatic or biological interference. Beyond contamination control, they also shield pipettes from corrosive reagents or viscous samples that could degrade internal components over time.

In this article, we’ll explore why filter tips are non-negotiable in modern labs, unpack how their design combats contamination risks, and address common concerns—such as their efficacy in RNase-free workflows and compatibility with precision pipetting. Whether you’re handling toxic compounds or amplifying delicate genetic material, understanding these nuances ensures your science stays precise, reproducible, and truly protected.

Why Use Filter Pipette Tips?

1. Preventing Aerosol Contamination

During routine pipetting, rapid liquid dispensing or mixing can generate microscopic aerosols (particles <10 µm). These aerosols easily travel through standard non-filtered tips and enter the pipette barrel, contaminating subsequent samples and compromising data integrity. Filter pipette tips address this risk with a hydrophobic barrier—typically made of polyethylene (PE) or polypropylene (PP)—that blocks aerosols and liquid from passing upstream. The material’s low surface tension repels aqueous solutions and traps particles, ensuring only the intended liquid is transferred.

2. Protecting Pipette Internal Components

Biological samples (e.g., RNA, bacteria), corrosive reagents, or viscous fluids can leave residues inside pipette barrels. Over time, these residues degrade critical components like piston seals and O-rings, leading to calibration drift or mechanical failure. Filter tips act as a physical shield, preventing direct contact between hazardous substances and the pipette’s interior. For example, RNase-containing samples can deposit enzymes on non-filtered tips, which may later interfere with RNA-sensitive workflows.

3. Enhancing Experimental Reproducibility

Contamination from aerosols or carryover is a leading cause of false positives/negatives in high-sensitivity assays. In qPCR, trace genomic DNA contamination can amplify non-specific signals, while in cell culture, mycoplasma or endotoxin transfer via aerosols can ruin entire experiments. Filter tips minimize these risks, ensuring consistent results—especially when handling low-concentration targets (e.g., single-cell RNA) or precious samples.

4. Compliance with Regulatory Standards

In regulated environments like clinical diagnostics (ISO 15189), GMP facilities, or virology research (BSL-2+), the use of filter tips is often mandatory. These settings demand adherence to strict contamination control protocols to ensure patient safety, product quality, or biosafety compliance. For instance, FDA guidelines for COVID-19 testing require filtered tips to prevent PCR cross-reactivity and false diagnoses.

How Do Filter Pipette Tips Work?

1. Filter Material: The Science of Hydrophobicity and Pore Optimization

The filter’s core is a membrane crafted from polyethylene (PE) or polypropylene (PP)—polymers with inherently low surface energy. This property gives them strong hydrophobicity (water contact angles >90°), causing aqueous liquids and aerosols to bead up rather than penetrate.

Pore Size Engineering:

Filters are laser-drilled with pores ≤20 µm in diameter—small enough to block aerosols (typically 0.5–10 µm) and biomolecules (e.g., RNase at ~3.5 nm but often carried by larger particles), yet large enough to permit smooth airflow for volumetric accuracy.

Example: In RNA extraction, submicron RNase particles bind to aerosols or debris; the 20 µm pores trap these complexes, preventing enzyme migration.

2. Dual Protection: Physics Meets Chemistry

A. Physical Filtration: The First Line of Defense

The hydrophobic filter acts as a mechanical sieve:

Aerosols generated during pipetting (e.g., bubble bursting in PCR tubes) collide with the filter and adhere due to surface tension.

Liquid splashes (e.g., organic solvents) are repelled, avoiding capillary action into the pipette.

B. Chemical Inertness: Eliminating Hidden Risks

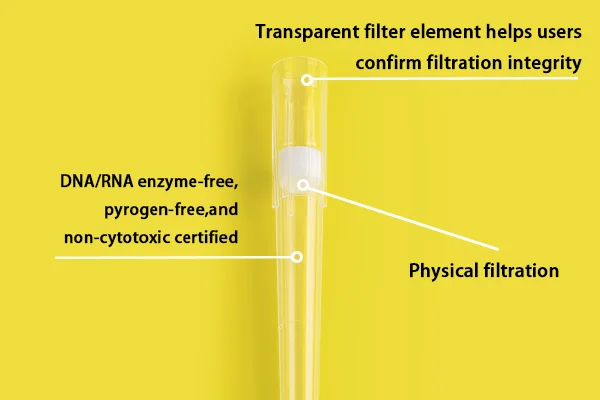

Even the filter material itself must be nonreactive:

Filter tips need to pass the following certifications:

RNase/DNase-free: Validated via fluorometric assays (e.g., using RNaseAlert® kits) to ensure no enzymatic degradation of nucleic acids.

Endotoxin-free: Tested with Limulus Amebocyte Lysate (LAL) to levels <0.001 EU/mL, critical for cell culture and in vivo applications.

3. Visual Design: Transparency as a Functional Feature

The filter housing is often transparent, not just for aesthetics but for real-time quality control:

Users can inspect for physical defects (e.g., cracks from improper handling).

Clog detection: Viscous samples (e.g., blood or glycerol solutions) may partially block pores; visual checks prevent volume inaccuracies.

Filter Pipette Tips FAQs

Q1: How effective are filter tips for RNase-free work?

Certified filter tips reliably protect against RNase/DNase contamination in molecular biology workflows. This is ensured by:

Independent validation: Third-party testing confirms residual RNase/DNase levels <0.001 pg/µL, compliant with PCR/NGS requirements.

Manufacturing standards: Production under ISO 13485 and USP Class VI guarantees contaminant-free environments and inert materials.

Q2: Do filter tips reduce pipetting accuracy?

High-quality filter tips, when used correctly, generally do not significantly reduce accuracy. Potential minor errors may arise from:

Filter resistance (critical for viscous liquids).

Poorly manufactured tips (uneven filters, material deformation).

User error (improper sealing, incorrect immersion depth).

Q3: How to avoid accuracy loss with filter tips?

Use tips recommended by the pipette manufacturer.

Calibrate pipettes regularly, especially for viscous/volatile liquids.

Pre-wet tips for hydrophobic liquids.

Ensure tight sealing and avoid rapid plunger movements.

Q4: When must filter tips be used despite potential accuracy concerns?

Prioritize filtration protection in:

Pathogen handling, RNA work, or aerosol-prone liquids (e.g., chloroform).

Pipetting corrosive substances (acids, organic solvents).

Sensitive experiments (qPCR, cell culture) to prevent cross-contamination.

Q5: Can filter tips improve accuracy in some cases?

Yes. They stabilize volatile liquids (e.g., ethanol) by reducing evaporation and block bubbles in foamy samples, enhancing consistency.

Q6: Can filter tips be reused?

No, they are designed for single use due to:

Cross-contamination risk: Residual samples (e.g., DNA, chemicals) may persist even after cleaning, compromising sensitive experiments.

Filter damage: The filter (often porous material) can degrade, failing to block aerosols/liquid backflow and risking pipette contamination.

Sterilization issues: Autoclaving may deform tips or melt filters, reducing sealing accuracy.

Reduced precision: Reused tips may leak or retain residues, affecting volume accuracy, especially for microliter transfers.

Manufacturer guidelines: Most brands explicitly state “single-use only” to ensure reliability and compliance.

Q7: Are filter tips compatible with all pipette brands?

Filter tips are generally not universally compatible with all brands of pipettes, but universal pipette filter tips that are compatible with multiple brands of pipettes do exist (e.g. Thermo Scientific Finntip Flex, GenFollower Universal Filter Tips). Their compatibility has the following requirements:

Precision engineering: Tips must match nozzle dimensions (e.g., ±0.05 mm diameter tolerance) to ensure airtight seals.

Certification: Use manufacturer-validated tips or ISO 8258-compliant products.

Q8: Do filter tips increase experimental costs?

In fact, filter tips do not increase the long-term costs of the laboratory. Although the upfront cost increases by 20-30%, they reduce other costs accordingly:

Contamination losses: CDC data shows filter tips lower repeat experiment rates by ~50% in PCR workflows.

Equipment repairs: Filters prevent 200−500 pipette repairs by blocking liquid ingress.

Q9: When to use filter tips vs. filterless tips?

Filter tips and non-filter tips have different application scenarios.

Use filter tips for:

Sensitive assays (PCR, cell culture, pathogen handling).

Volatile/organic liquids (e.g., chloroform, phenol).

Use filterless tips for:

Routine transfers of non-critical liquids (buffers, non-nucleic acids).

Low-risk workflows with strict budget constraints.

How to Select the Appropriate Filter Tips?

1. Filtration Efficiency

Requirement: Choose tips with ≥99% aerosol retention to prevent cross-contamination.

Validation: Look for manufacturers that use standardized testing methods (e.g., methylene blue aerosol tests or fluorescent particle assays). For example, Eppendorf’s LoBind filter tips demonstrate 99.7% retention of 0.2–5 µm particles, validated via ISO 8655-compliant protocols.

Caution: Avoid tips lacking quantitative filtration data, as incomplete retention compromises sensitive workflows (e.g., qPCR, cell culture).

2. Certification Scope

Critical Certifications:

RNase/DNase-free: Essential for nucleic acid workflows (PCR, NGS). Verified via in vitro RNase activity assays (e.g., ≤0.001 pg/µL residual activity).

PCR Inhibitor-free: Certified through spike-and-recovery tests (e.g., 95–105% recovery rates for Taq polymerase).

Endotoxin-free: Required for cell culture or in vivo applications (e.g., <0.001 EU/mL, compliant with USP <85> guidelines).

Trusted Standards: Prioritize tips certified under ISO 13485 (medical device manufacturing) or USP Class VI (biocompatibility).

3. Pipette Brand Compatibility

Universal vs. Brand-Specific Tips:

Universal Tips: Fit multiple pipette brands (e.g., Rainin LTS, GenFollower Universal) but require validation of airtight seals (tolerance ≤±0.05 mm in nozzle diameter).

Brand-Specific Tips: Engineered for precision (e.g., Thermo Fisher Finntips for Multiskan™ pipettes), ensuring optimal accuracy (±0.5% CV for 10 µL volumes).

Validation Step: Perform a “tip ejection force test” – excessive resistance (>5 N) indicates poor compatibility.

4. Packaging Format

Individually Wrapped Tips:

Use Case: High-risk environments (BSL-2+ labs, clinical diagnostics) to minimize airborne contamination.

Drawback: 20–30% higher cost compared to bulk packaging.

Bulk/Racked Tips:

Use Case: Routine applications (e.g., buffer preparation) in low-contamination settings.

Risk Mitigation: Select racks with UV-resistant lids and desiccant packs to maintain sterility.

5. Application-Specific Recommendations

Molecular Biology (PCR, NGS)

Priority use certified RNase/DNase-free and PCR Inhibitor-free tips.

Avoid Non-certified tips, which may introduce genomic DNA or inhibit reverse transcription.

Virology or Toxic Sample Handling

Priority: Tips compliant with BSL-2+ containment requirements.

Features:

Aerosol-tight filters: Retain viral particles (e.g., SARS-CoV-2, ~0.1 µm) via multi-layer hydrophobic membranes.

Biosecurity Packaging: Individually wrapped tips with tamper-proof seals.

Reference: Align with CDC-NIH Biosafety in Microbiological and Biomedical Laboratories (BMBL 6th Edition).

Cell Culture and Protein Studies

Priority: Endotoxin-free and non-cytotoxic tips.

Organic Solvent Pipetting

Priority: Tips with chemical-resistant filters (e.g., PTFE membranes).

Conclusion

Selecting the right filter tips hinges on aligning filtration efficiency, certifications, brand compatibility, and packaging with your experimental needs. For molecular biology (e.g., PCR, NGS), prioritize tips with validated RNase/DNase-free and PCR inhibitor-free certifications. In virology or toxic workflows, opt for aerosol-tight filters in secure packaging to meet biosafety standards. Universal tips offer flexibility, while brand-specific designs ensure precision for critical applications.

For researchers seeking high-performance solutions, GenFollower provides premium filter/non-filter tips engineered to elevate lab workflows:

Broad size range: 10 µL to 1250 µL, suitable for diverse protocols.

Universal compatibility: Optimized for Eppendorf, Gilson, Thermo Scientific, and other major pipette brands.

Certified quality: Compliant with ISO 13485 and ISO 9001 standards, with patented innovations enhancing reliability.

Sustainable design: 20% reduction in plastic usage without compromising durability.

Customization: Specialized options like double-layer filters or self-sealing membranes for advanced applications.

By integrating rigorous quality control with user-centric design, GenFollower tips minimize contamination risks while supporting precision across genomics, diagnostics, and cell culture workflows.

What is Cell Therapy Manufacturing?Essentials and manufacturing processes for cell therapies

Cell therapy is rewriting the rules of modern medicine. Imagine a treatment that uses a patient’s own immune cells, reprogrammed in a lab to hunt down and destroy cancer—this is no longer science fiction [...]

Why use filter pipette tips? A Comprehensive Guide to Filter Pipette Tips

In laboratory workflows, unseen threats like aerosol contamination, residual liquid carryover, and cross-contamination can silently sabotage experimental results. This is where filter pipette tips step in—not just as disposable tools for liquid handling, but [...]

The Comprehensive Guide to Centrifuge Tubes

Centrifuge tubes are indispensable tools in modern laboratories, enabling the separation of samples by density through high-speed spinning. Widely used in scientific research, medical diagnostics, and industrial processes, these tubes play a critical role [...]