Molding

Custom Your Mould

We specialize in custom molding for plastic labware like microtubes, pipette tips, plates, racks, and more. Our passion is crafting perfect solutions just for you.

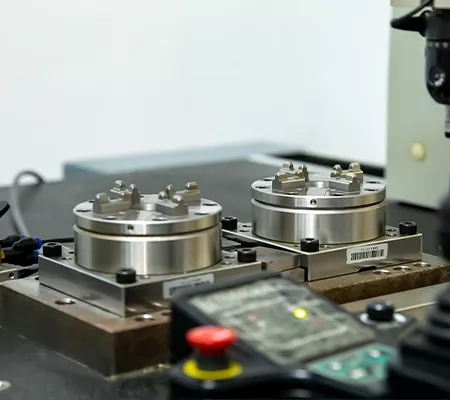

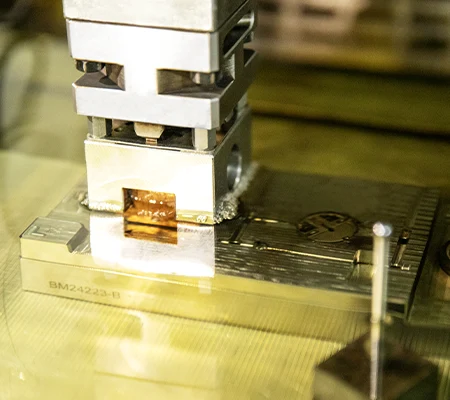

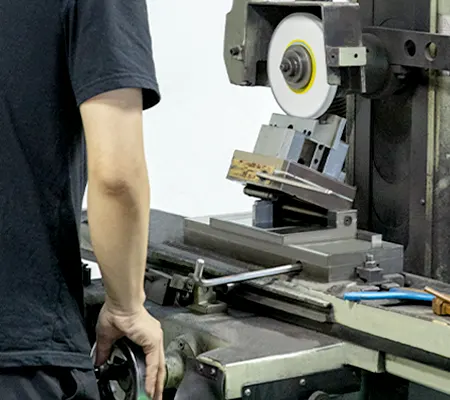

Custom Moulds

We specialize in manufacturing moulds for lab consumables. With extensive experience and expert engineering support, you can select from two customized solutions designed to meet your exact requirements.

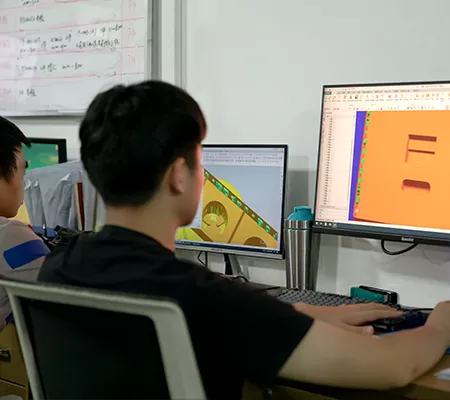

Email us your designs and technical requirements.

We’ll review your specifications and provide a detailed quote for the mold, a separate quote for OEM production, and an estimated project timeline.

If you agree to the terms, we’ll need a 60% deposit of the total cost.

Once we receive the deposit, we’ll begin working on your project.

Ship at least five pieces of your sample to us via express courier.

Email us your specific product requirements.

We’ll evaluate the project and suggest any necessary changes to the sample.

Once you approve the design, we’ll provide a detailed quote and timeline.

After you’re satisfied and have approved everything, we’ll need a 50% deposit to begin the work.